iD Indicator

- Dual operating language option – display all test setup menu programs in either English or Spanish.

- Automatically calculates and displays peak stress at the end of a test.

The iD indicator is the system of choice for testing programs where accuracy, ease of operation, test documentation and dependability are required. During a test it simultaneously displays load, sample stress, rate of load, and the type and size of the sample being tested in large easy to read alphanumeric characters.

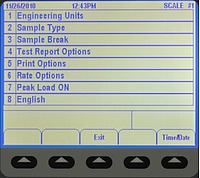

Its user friendly setup menu with English or Spanish language option displays all menu option listings simultaneously, allowing the operator to quickly access the required menu and simply press a key to activate it or enter a numeric value to set a test parameter. This display feature eliminates the time consuming method of scrolling through single line displays to find an option and then set its function.

Its sample type menu lists six common specimen types to select from; cylinder, cube, beam third point, beam center point, cylinder split in tension and cross-sectional area. Just select and set. Its innovative Sample Size key speeds up test data entry by allowing you to reset a sample dimension from its standard testing screen, eliminating the need to enter its normal setup menu procedures. Test results can be automatically stored for hard copy documentation.

All information is clearly displayed on the indicators 4.6” W x 3.4” H (116 x 86 mm) back-lit VGA graphic panel display. Its 320 x 240 pixel screen with adjustable contrast is easily read in both bright and poor lighting conditions. Large alphanumeric characters display test data in any of the selectable engineering units, force units of lbs, kN, kg and N, stress units of psi, MPa, kg/cm² and Kpa, size units of in, mm and cm, and time units of seconds or minutes.

For test documentation the indicator can be set to automatically store test results to memory for downloading to a PC or printed by the indicator. Up to 500 tests can be stored to memory and transfer them directly into a Word document or spreadsheet file with the optional USB Able Cable. Information includes; test date and time, sample ID alphanumerically, sample type, sample area and length, peak load and peak stress. Optional data includes; average rate of load applied to a sample during a test, cylinder correction factor to C-39, cylinder break type, cylinder cap type, sample age and weight, and operator ID number.

Built for the harshest laboratory environments, the indicator features a NEMA-4 stainless steel enclosure that is both moisture and dust proof, heavy duty tactile feel keys with stainless domes tested to over five million actuations. Its approvals and listings are; UL, CUL, CE, Measurement Canada and FCC.

The iD features a smooth and more uniform control of load pacing rates through its high speed sampling rates and digital filtering. Accuracy exceeds ASTM C-39 and E-4 requirements and is achieved through a calibration program with five linearization points, and in general is better than ±.5% of indicated load from 1% to full machine capacity. Up to three separate calibration programs can be stored allowing the indicator to be used with multiple transducer/load cell combinations with one or more testing machine load frame. Its calibration program is password protected.

Power requirement is 115/60/1 or 230/50/1

The iD indicator is available as a retrofit package for field installation.